Introduction to Pasteurization Machine:

Pasteurization machine were first developed in the 19th century by French microbiologist Louis Pasteur to kill harmful bacteria in wine. The process involves heating a liquid or food product to a specific temperature for a set time and then rapidly cooling it down to prevent further bacterial growth.

Applications of Pasteurization Machine:

Pasteurization equipment are widely used in the food and beverage industry to extend the shelf life of perishable products such as milk, juice, beer, and canned foods. They are also used in pharmaceutical manufacturing to sterilize drugs and medical equipment.

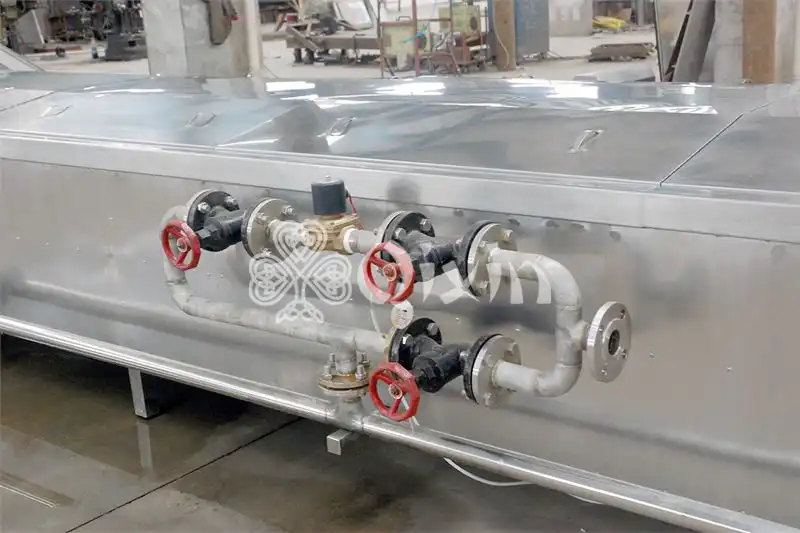

Features of Pasteurization Machine:

Some of the critical attributes of pasteurization machines include the following:

1. Precise temperature control to ensure consistent results

2. Automatic shut-off systems to prevent over-processing

3. Stainless steel construction for easy cleaning and sanitation

4. Customizable settings for different products and production volumes

5. Energy-efficient designs to reduce operating costs

Problems to Pay Attention to When Using Pasteurization Machine:

When using pasteurizer machine, it is essential to pay attention to the following issues:

1. Proper calibration of temperature sensors to ensure accurate readings

2. Regular maintenance and cleaning to prevent bacterial buildup and equipment failure

3. Adequate cooling to avoid overheating and product spoilage

4. Proper handling and storage of processed products to maintain their quality and safety

5. Compliance with regulatory standards and guidelines for food processing and safety.

Pasteurization Machine Parameters:

| Model | Power | Weight | Size |

|---|---|---|---|

| LPT3000 | 40.87kw/380v | 400kg | 3000*1000*1400mm |

| LPT4000 | 54.37kw/380v | 500kg | 4000*1000*1400mm |

| LPT5000 | 81.75kw/380v | 600kg | 5000*1000*1400mm |

| LPT6000 | 108.25kw/380v | 700kg | 6000*1000*1400mm |

Conclusion:

Pasteurization machines have revolutionized the food and beverage industry by helping to reduce food waste and improve product safety and quality.

By carefully controlling perishable products' temperature and processing time, these machines can effectively kill harmful bacteria and extend the shelf life of many food and beverage products. However, careful attention must be paid to the use and maintenance of these machines to ensure their safety and effectiveness.

Leave a Message now!