Introduction of Picking Conveying Machine:

A Picking Conveying Machine is a conveyor system designed to move products or

materials from one place to another in a warehouse or distribution center. The

system consists of a series of belts, chains, or rollers that are used to move

the product along the conveyor line.

Application of Picking Conveying Machine:

Picking Conveying Machines are commonly used in warehouses and distribution centers to move products from storage areas to picking stations where workers can retrieve the products they need for orders.

They are also used in manufacturing facilities to transport finished products from assembly lines to packaging and shipping areas.

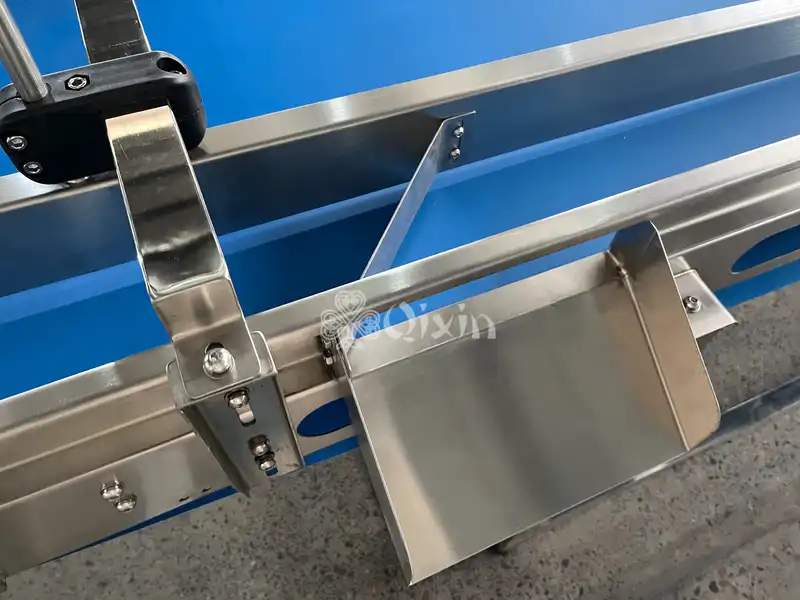

Features of the Picking Conveying Machine:

High Efficiency:

The Picking Conveying Machine is designed to move products

quickly and efficiently through the warehouse or manufacturing facility.

Customizable:

The system can be customized to fit the facility's specific needs. Conveyor widths, lengths, and product spacing can all be adjusted to meet the requirements of the operation.

Safety Features:

The Picking Conveying Machine is equipped with safety features such as emergency stop buttons and sensors that detect obstructions or jams in the system.

Low maintenance:

The system is designed to be low maintenance, with minimal moving parts and easy access for cleaning and maintenance.

Versatility: The Picking Conveying Machine can handle many products, from small items like electronics and pharmaceuticals to larger items like furniture and appliances.

Picking Conveying Machine Parameters:

| Model | Power | Weight | Size |

|---|---|---|---|

| DY | 0.37KW/380v | 90kg | 4000*1000*1100mm |

Conclusion:

The Picking Conveying Machine is essential to many warehouse and manufacturing operations. It offers high efficiency, customizability, safety features, low maintenance, and versatility.

However, proper maintenance, loading, training, monitoring, and lubrication are necessary to ensure safe and efficient operation.

By adhering to these guidelines, facilities can maximize the benefits of the Picking Conveying Machine and improve their overall productivity.

Leave a Message now!