Introduction of Full Automatic Potato Chips Processing Line:

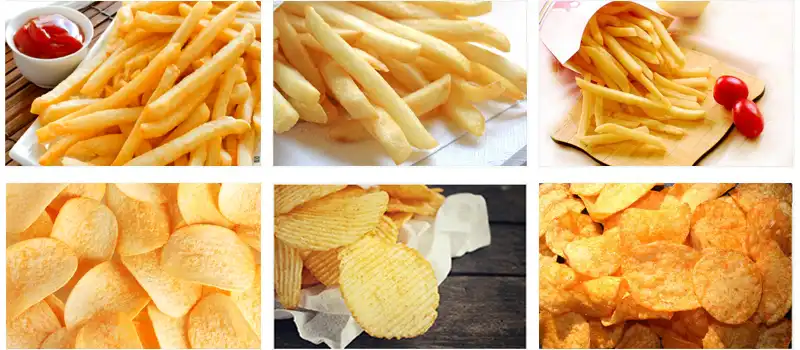

The Full Automatic Potato Chips Processing Line is a complete solution for

making high-quality potato chips on a large scale.

It includes a series of machines designed to handle every step of the potato chip production process, from washing and peeling to slicing, blanching, frying, seasoning, and packaging.

Main Machines included in the Full Automatic Potato Chips Processing Line:

Potato washing and peeling machine:

Removes dirt, peel, and other impurities from the potatoes.

Potato slicing machine:

Slices the potatoes into thin and uniform pieces.

Blanching machine:

Precooks the potato slices to remove excess starch and improve their texture.

Frying machine:

Deep-fries the potato slices to make them crispy and golden brown.

Seasoning machine:

Adds flavorings or coatings to the potato chips.

Packaging machine:

Packs the chips into bags or containers.

Features of the Full Automatic Potato Chips Processing Line:

High efficiency:

The line can process a large amount of potatoes quickly and continuously.

Consistent quality:

The machines ensure that the potato chips are uniform in size, color, and texture.

Customizable:

The line can be tailored to meet different customers' specific needs and preferences.

Easy operation:

The machines are user-friendly and require minimal training.

Hygienic and safe:

The line is made of food-grade materials and designed to meet strict sanitation and safety standards.

Precautions of Full Automatic Potato Chips Processing Line:

1. Operators should receive proper training on how to operate the machines safely.

2. Regular maintenance and cleaning of the machines are required to prevent breakdowns and ensure the quality of the potato chips.

3. The production line should be inspected regularly to ensure all components function correctly.

Conclusion:

The Full Automatic Potato Chips Processing Line is a reliable and efficient solution for producing high-quality potato chips.

It offers various benefits, such as improved productivity, consistent quality, and customization options, making it a worthwhile investment for businesses in the snack food industry.

Leave a Message now!