Introduction of Semi-automatic potato chips line

The semi-automatic potato chips processing line is a set of machines designed

to process raw potatoes into crispy, tasty potato chips.

The line includes machines for washing, peeling, slicing, blanching, frying, and seasoning the potato chips.

This line is an ideal choice for small to medium-sized potato chip producers who want to increase their production efficiency while maintaining some manual control over the process.

The equipment included in a semi-automatic potato chip processing line can vary depending on the specific needs and preferences of the potato chip producer.

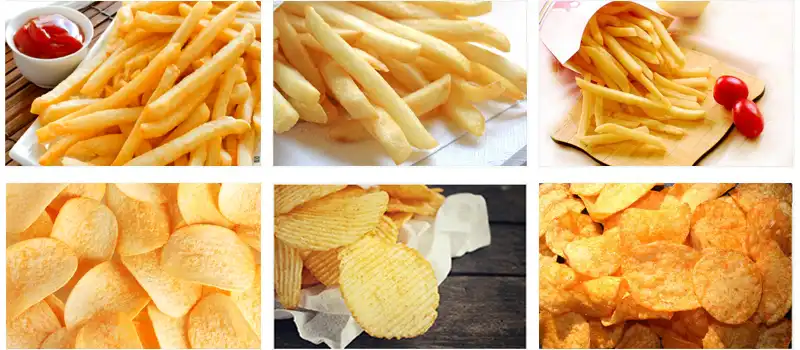

Main products of the Semi-automatic potato chips line

However, the following are some of the machines commonly included in a standard semi-automatic potato chips processing line:

Potato Washing Machine:

This machine is used to wash and remove dirt from raw potatoes before they are processed.

Potato Peeling Machine:

This machine peels the skin off the potatoes, which is necessary before slicing.

Potato Slicing Machine:

This machine is used to slice the peeled potatoes into thin slices of uniform thickness.

Blanching Machine:

This machine is used to blanch the sliced potatoes in hot water for a short period to remove excess starch and ensure even frying.

Potato Chips Frying Machine:

This machine is used to fry the sliced potatoes in hot oil until they are crispy and golden brown.

De-oiling Machine:

This machine is used to remove excess oil from the fried potato chips, which helps to improve their texture and taste.

Flavoring Machine:

This machine adds flavorings, such as salt or other seasonings, to the finished potato chips.

Sorting Machine:

This machine inspects and sorts the finished potato chips, removing any defective or subpar chips.

Packaging Machine:

This machine packages the finished potato chips into bags or containers for sale.

These machines work together in a semi-automatic potato chips processing line to transform raw potatoes into finished potato chips, ready for consumption.

Characteristics of Semi-automatic potato chips line

Here are some key characteristics of the semi-automatic potato chips processing line:

1. The line comprises several machines that work together to produce high-quality potato chips.

2. The machines are made of high-quality materials, which ensures durability and long service life.

3. The line can be customized to meet the specific needs of the potato chip producer, such as adjusting the thickness of the potato slices or the frying temperature.

4. The line is easy to operate and maintain, reducing the need for skilled labor and reducing production costs.

5. The line has a high production capacity, which allows for processing large quantities of raw potatoes into finished potato chips in a short period.

Precautions of Semi-automatic potato chips line

Here are some precautions that need to be taken when using the semi-automatic potato chips processing line:

1. Ensure the machines are correctly installed and connected to the power supply before use.

2. Check the machines regularly for signs of wear and tear, and replace damaged parts immediately.

3. Clean the machines thoroughly after each use to prevent the build-up of dirt and debris, which can affect the quality of the potato chips.

4. Monitor the frying temperature closely to avoid overheating the oil, which can lead to burning and unevenly cooked chips.

5. Make sure that the potato slices are evenly cut and of a consistent thickness to ensure that the chips are cooked evenly and have a uniform texture.

Conclusion

The semi-automatic potato chips processing line is a versatile and efficient set of machines that can help small to medium-sized potato chip producers increase their production capacity while maintaining some level of manual control over the process.

The line has several key characteristics that make it a popular choice for potato chip producers, including its high production capacity, ease of operation and maintenance, and ability to be customized to meet specific production needs.

However, taking precautions when using the line is essential to ensure that it operates safely and produces high-quality potato chips.

Leave a Message now!